[SBA Global] RGT Aims to Expand Worldwide with Korea’s Autonomous Serving Robots

Sat, Feb 15 2025

![[SBA Global] RGT Aims to Expand Worldwide with Korea’s Autonomous Serving Robots](https://wghivirhjfxgpwsocfmy.supabase.co/storage/v1/object/public/press_banners/press:banner:F20-PYr12l6Rogxmk6782.jpg)

The robotics industry, along with artificial intelligence, has long been recognized as a key driver of future economic growth. Major domestic and international corporations are actively investing in robotics, expecting these technologies to play a leading role in various industries, including manufacturing, healthcare, logistics, and services. The startup market is no exception. Although challenging, many startups are boldly entering the robotics industry with innovative technology and ideas.

RGT (Robot Global Team) is an emerging robotics startup specializing in service robots, developed entirely with Korean technology. The company manages all aspects of the robotics process, from planning and development to production, distribution, and management. RGT has achieved notable success and continues to make its mark in the industry. We spoke with CEO Ho-jung Jung to explore his vision for the future of robotics.

What kind of robotics startup is RGT?

RGT is a total solution provider for service robots based on autonomous driving technology. Founded in 2018, the company develops various robots, including serving robots commonly seen in large retail stores, as well as guidance, cleaning, delivery, and security robots. In addition to autonomous driving technology, RGT also focuses on robot automation systems, encompassing all aspects of robot operations. For example, in the case of cooking robots, this includes automated cooking solutions.

RGT’s name stands for "Robot Global Team," reflecting its ambition to expand beyond Korea into the global market. The company currently exports its service robots to more than 12 countries, including the United States, the United Kingdom, China, Vietnam, and Pakistan. RGT also collaborates with top local talent in these regions.

What motivated you to launch a startup in the robotics industry, which is known to be particularly challenging?

The reason for starting the company wasn’t particularly grand. While studying autonomous driving at university, I heard from my aunt, who was running a franchise business in the U.S., about the challenges she faced in managing her workforce. Despite good sales, she struggled with high employee turnover, making it difficult to focus on operations.

As an engineer and developer, I saw the need for standardized and systemized operations. Reducing the workload for employees became the top priority, which led me to the idea of developing a serving robot using my expertise in autonomous driving. After researching similar challenges in other countries like Japan and Australia, I founded RGT in 2018. (Unfortunately, my aunt’s business eventually closed.)

What types of service robots does RGT currently develop and supply?

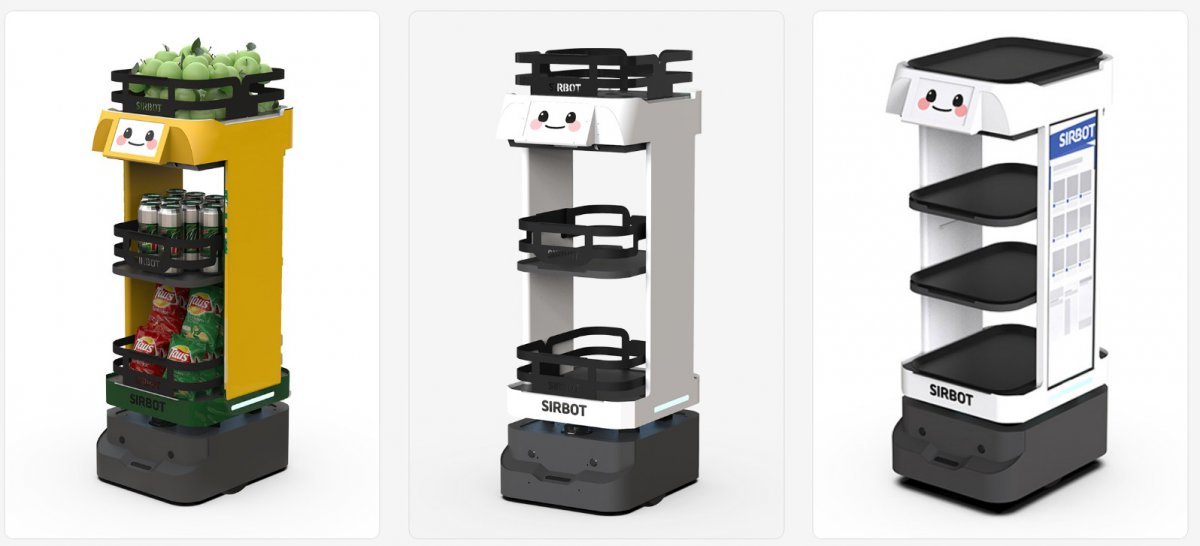

Our serving robot, SIRBOT, is now in its third generation and has been deployed in various stores and spaces worldwide. We also develop logistics robots for factories, promotional/sales robots for department stores and large retail outlets, and early-stage guidance and security robots for large venues and buildings. All of these robots are built on our core autonomous driving technology, combined with custom software and systems tailored for each use case.

Can you share a success story where RGT's service robots made a real impact?

One of the most memorable customers was an elderly couple running a small restaurant. The husband had mobility issues, making it difficult to operate the business. After researching serving robots, they decided to purchase our SIRBOT. When I visited them a few months later, they expressed their gratitude, saying that the robot had significantly eased their workload. The experience reinforced my commitment to improving our technology.

Currently, over 2,000 RGT robots are deployed across Korea, assisting customers in various industries.

How does RGT differentiate itself in the competitive serving robot market?

Many serving robots in Korea, whether from large corporations or startups, are actually imported from the U.S. or China, as Chinese robots often provide good price-to-performance value. However, RGT’s robots are 100% domestically developed and produced, specifically optimized for service environments.

One key difference is that service spaces, such as restaurants and hotels, often have reflective surfaces like glass walls and glossy floors, which can interfere with optical sensors used in autonomous navigation. RGT's robots are designed to navigate stably in these challenging environments.

Additionally, our robots can track and predict the movement paths of people in real-time to avoid collisions and operate smoothly in crowded spaces. Unlike industrial robots that work in controlled environments, service robots must anticipate human movement and adjust accordingly—something we’ve carefully engineered into our systems.

Some argue that serving robots may replace human jobs. How do you see the relationship between robots and human workers?

Occasionally, customers ask if deploying a serving robot means they can cut one employee from their workforce to save labor costs. While that may be true in some cases, I don’t recommend viewing robots solely as a way to reduce headcount.

Instead, robots should be used to ease the workload of employees so they can focus on customer interaction and service quality—something that robots currently cannot replace. For example, a waiter freed from carrying plates can focus on engaging with guests, improving customer satisfaction, and potentially increasing revenue.

A great example is the elderly couple I mentioned earlier. With a serving robot handling food delivery, the restaurant owner could spend more time chatting with customers and fostering relationships.

RGT has also developed cooking robots. What kinds of dishes can they prepare?

We started with barista robots in 2019, supplying them to public institutions. These robots handle everything from ordering and payment to brewing coffee and serving it using robotic arms—similar to what you now see in some major shopping malls.

We’ve also developed frying robots capable of preparing fried chicken, fries, donuts, and pork cutlets, as well as noodle-cooking robots. For these cooking robots, we integrate robotic arms from specialized manufacturers and develop custom grippers (robotic hands) to perform specific cooking tasks. Our automation solutions and software ensure smooth operation.

RGT manufactures its robots domestically. What is your current production capacity?

We collaborate with multiple robotics manufacturing facilities in Korea and currently produce about 200 robots per month. Since all production is domestic, we have a competitive edge in technical support and after-sales service compared to companies that rely on imported robots. We also have an in-house support team, although we’re still looking to expand our R&D and development workforce. About 70% of our 30 employees are engineers.

RGT is receiving support from SBA (Seoul Business Agency) for international expansion. What does this support entail?

SBA is helping us enter the Japanese market. They’ve connected us with a local company for proof-of-concept (PoC) testing and are assisting with the groundwork for distributing our robots in Japan. This is our second attempt to enter the Japanese market, and with SBA’s support, we are optimistic about achieving meaningful results.

What are RGT’s goals for 2024 and 2025?

As a startup, there’s always room for growth, but we are satisfied with our achievements this year. In 2025, we aim to increase sales, launch new products, and continue expanding internationally. We are also planning to showcase our innovations at CES 2025 in Las Vegas as part of our strategy to establish RGT as a top-tier robotics startup.

Source: Dong-A Ilbo Copyright: RGT